If you’re someone who frequently finds themselves relying on screw guns for various projects, you understand the importance of a tool that delivers top-notch performance. In our search for the best gadgets that can make our lives easier, we often stumble upon brushless motors as a buzzworthy feature. But do they really live up to the hype? Can screw guns equipped with brushless motors truly take your performance to the next level? Join us as we delve into this topic, aiming to provide answers to your burning questions and help you make an informed decision when it comes to picking the perfect screw gun for your needs.

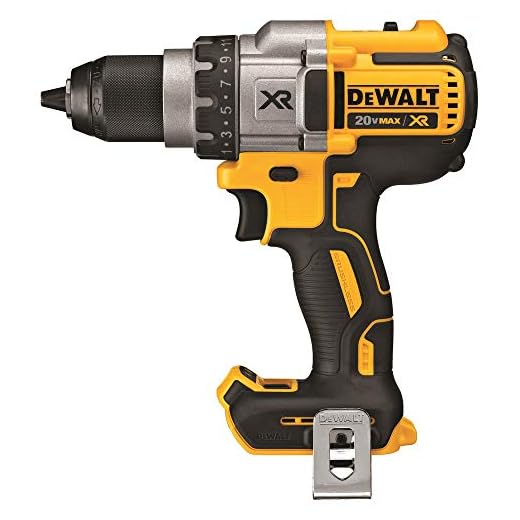

Top-rated Screw Guns for all your DIY Needs

Understanding Brushless Motors

In the world of power tools, motors play a crucial role in providing the necessary torque and power. Traditionally, brushed motors have been the go-to choice for many industries, including construction and manufacturing. However, in recent years, brushless motors have emerged as a game-changer, bringing significant advancements and numerous benefits. This blog post aims to demystify brushless motors, highlighting their advantages over conventional brushed motors found in screw guns.

Brushed Motors: The Old Technology

Brushed motors have long been the workhorses of power tools. Consisting of brushes and a commutator, these motors use direct current (DC) to produce rotating motion. Here’s how a brushed motor typically operates:

- Electrical current is transmitted through carbon brushes to the commutator.

- The commutator changes the direction of the electrical current at specific points.

- This alternating current interacts with the rotor’s electromagnetic field, resulting in rotational motion.

While brushed motors have been around for decades and served their purpose, they come with several limitations and drawbacks:

- Friction and Wear: The brushes in brushed motors create friction against the rotating commutator, causing gradual wear and tear over time. As a result, regular maintenance, such as brush replacement, is necessary.

- Lower Efficiency: Due to the brush-to-commutator contact, energy is lost as heat. This inefficiency not only affects the power output but also decreases the overall endurance of the motor.

- Limited Lifespan: The wear and tear on the brushes and commutator shorten the motor’s lifespan, making it suitable for fewer working hours compared to brushless motors.

Discovering the Advantages of Brushless Motors

When it comes to enhanced power tools performance, brushless motors have brought about a revolution. These motors, unlike their brushed counterparts, break away from traditional design and boast remarkable advancements. Let’s delve into the benefits that brushless motors offer over their brushed counterparts:

Improved Efficiency and Power

Brushless motors eliminate many of the inefficiencies associated with brushed motors. By utilizing electronic control, brushless motors optimize power usage, resulting in increased efficiency.

Here’s why brushless motors charge ahead in terms of power and efficiency:

- No Brush Friction: Unlike brushed motors, brushless motors don’t rely on physical brushes touching the commutator. As a result, friction is minimized, and no energy is wasted in heat production.

- Electronic Commutation: Brushless motors employ electronic control to precisely synchronize the power delivery to the rotor. This technique eliminates power losses from conventional commutation methods, making the motor operate at its maximum potential.

- More Torque: Brushless motors generate higher torque output due to their superior design, enabling them to handle demanding tasks effortlessly.

Reduced Maintenance

Maintenance is often a time-consuming and costly factor, particularly in industries relying heavily on power tools. One significant advantage of brushless motors is their maintenance-free operation. Here’s why maintenance is minimized with brushless motors:

- No Brushes to Replace: As brushless motors don’t use brushes, there’s no need to replace them periodically, reducing upkeep costs and downtime.

- No Commutator Cleaning: Traditional brushed motors require regular commutator cleaning, as carbon brushes leave residue behind. With brushless motors, the absence of brushes eliminates this cleaning chore entirely.

- Improved Longevity: Brushless motors, thanks to their reduced wear and tear, offer longer lifespans, making them ideal for applications requiring extended and uninterrupted usage.

Enhanced Durability and Reliability

Building power tools that can withstand challenging working environments is crucial for users. Brushless motors excel in durability, providing robustness and reliability to the tool. Here’s why brushless motors outlast their brushed counterparts:

- Less Heat, More Durability: With no frictional contact between brushes and commutator, heat generation is significantly reduced. This absence of heat extends the motor’s lifespan, ensuring prolonged tool usage.

- Advanced Electronic Speed Control: By employing advanced electronic speed controllers, brushless motors deliver consistent power output regardless of load fluctuations. This feature enhances both the motor’s performance and its lifespan by reducing stress on internal components.

Enhanced Power and Speed

When it comes to power tools, the key factors that professionals look for are power and speed. A tool’s performance can make a world of difference in terms of productivity and efficiency on the job. One of the latest advancements in power tool technology is the integration of brushless motors in screw guns, which offer enhanced power and speed capabilities. In this article, we will explore how brushless motors can deliver higher torque, faster rotations, and greater control, resulting in improved performance.

Higher Torque for Increased Power

- A brushless motor is designed to provide higher torque compared to traditional motors.

- As there are no brushes and commutators in the motor, there is less friction and therefore less power loss.

- This means that more rotational force can be transferred to the screw or fastener, resulting in increased power.

Faster Rotations for Greater Speed

- Brushless motors provide faster rotations, allowing for quicker screwdriving.

- The absence of brushes eliminates the need for physical contact, reducing any energy loss related to friction.

- By increasing the motor’s RPM (rotations per minute), the tool can drive screws or fasteners at a rapid pace, improving productivity.

Greater Control for Precision Work

- Brushless motors offer better control over the tool’s speed and power output.

- With traditional brush motors, increasing power typically translates to higher speed, limiting the ability to maintain a steady driving force.

- Brushless motors, on the other hand, allow for more precise adjustments, enabling accurate screwdriving even in delicate materials.

- This greater control also helps ensure consistent and flush screw fastening, minimizing the need for rework.

Comparison: Brushed vs. Brushless Motors

To better understand the benefits of brushless motors, here’s a quick comparison against brushed motors:

| Brushed Motors | Brushless Motors || ————– | —————- || Friction, leading to heat

and power loss | No friction, minimal heat

and power loss || Lower torque andrpm limits | Higher torque andrpm capabilities || Limited control over speed/power output | Greater control over speed/power output || Brushes wear outand require maintenance | No brushes to wear out,

lower maintenance required |

As evident from the comparison, brushless motors outperform brushed motors in every aspect crucial for enhanced power and speed.

Longer Battery Life and Run-Time

Battery life is a crucial factor to consider when choosing a screw gun, especially for those working on large projects or in remote locations where frequent recharging may not be feasible. One technology that has revolutionized the power tool industry in this regard is the brushless motor. In this section, we will delve into how brushless motors contribute to longer battery life and extended run-time, providing users with more efficient and productive work sessions.

1. Understanding Brushless Motors and Battery Consumption

To grasp why brushless motors are superior when it comes to conserving battery power, we first need to understand their basic principles. Unlike brushed motors which rely on physical brushes to transmit electricity, brushless motors utilize magnets to generate rotational power. This fundamental difference has several consequential advantages:

- Reduced energy loss: Because brushless motors lack physical brushes, they don’t experience brush friction, resulting in less energy loss and increased overall efficiency. This means more power is used to turn the motor, translating into longer battery life and improved run-time.

- Intelligent power control: Brushless motors include advanced control systems that regulate their speed and torque precisely. This intelligent power control ensures that the motor delivers only the necessary amount of energy for the task at hand, eliminating wasteful electricity usage. Consequently, battery consumption is optimized, extending the time the tool can be operated before a recharge is required.

2. Energy Efficiency: An Advantage of Brushless Motors

If you’re wondering how brushless motors achieve superior energy efficiency, it’s thanks to their circuitry. In a brushed motor, the brushes constantly rearrange the electrical current’s polarity, consuming additional electricity. In contrast, brushless motors employ an electronic controller that sends pulses of electricity to the magnets, eliminating the need for brushes. This direct communication between the controller and the magnets reduces power loss, increasing battery life and run-time.

3. Increased Power-to-Weight Ratio

Apart from their energy efficiency, brushless motors offer another significant advantage – an increased power-to-weight ratio. This important ratio measures the amount of power a motor produces per unit of weight. By employing lighter and smaller materials, brushless motors provide equivalent or even higher power outputs compared to their brushed counterparts. These features carry several benefits:

- Ease of use: Lighter tools equipped with brushless motors can be operated for longer durations without causing excessive strain or fatigue to the user, improving overall productivity.

- Portability: With reduced weight, brushless motor integrated power tools become easily portable, facilitating transportation, especially when working at various sites or on challenging terrains.

4. Advantages at a Glance: Brushless Motors vs. Brushed Motors

Let’s summarize the key advantages of brushless motors over brushed motors in the form of a comparison table:

| Feature | Brushed Motor | Brushless Motor |

|---|---|---|

| Energy Efficiency | More energy loss due to brush friction | Less energy loss due to absence of physical brushes |

| Intelligent Power Control | Less precise speed and torque control | Advanced control system for optimized power delivery |

| Power-to-Weight Ratio | Lower ratio | Higher ratio |

Wrap up

Brushless motors have ushered in a new era of power tool performance – one that places emphasis on longer battery life and extended run-time. By eliminating the restrictions posed by brushed motors, brushless motors offer users the ability to work longer durations without sacrificing efficiency. Whether you’re a professional contractor or a DIY enthusiast, opting for a screw gun powered by a brushless motor will undoubtedly enhance your work experience. So, when making your next tool purchase, consider investing in the incredible benefits provided by brushless technology.

Durability and Reliability

When it comes to power tools, durability and reliability are of paramount importance. Whether you are a DIY enthusiast or a professional contractor, investing in tools that can withstand the rigors of daily use is essential. In this blog section, we will delve into the world of screw guns and explore how screw guns with brushless motors surpass their brushed counterparts in terms of longevity and dependability. Let’s take a closer look!

The Brushed vs Brushless Motor Dilemma

Before we dive into the benefits of brushless motors, it’s important to understand the fundamental difference between brushed and brushless motors.

- Brushed Motors:

- Traditional, older technology.

- Equipped with brushes and commutators that conduct electricity.

- Brushes create friction and wear down over time.

- Commutators are prone to electrical arcing, resulting in potentially hazardous spark generation.

- Suffer from heat build-up due to energy loss in the brushes and commutators.

- Frequent maintenance and part replacements required.

- Brushless Motors:

- Modern, advanced technology.

- Operate using a series of magnets and electronic components.

- Eliminate the need for brushes and commutators, reducing wear and minimizing the risk of electrical failures.

- Frictionless operation enhances efficiency and extends motor life.

- Less heat generation and energy loss.

- Virtually maintenance-free.

Now, let’s see why brushless motors outshine their brushed counterparts in terms of durability and reliability.

Improved Longevity: Say Goodbye to Brush Wear

One of the main advantages of brushless motors is the absence of brushes, known for their vulnerability to wear and tear. By removing these components, brushless motors experience minimal wear during operation, resulting in significantly longer lifespan compared to their brushed counterparts. This extended lifespan means less frequent replacements and reduced downtime for you.

Enhanced Reliability: Eradicating Electrical Arcing

Brushed motors suffer from electrical arcing, caused by the contact between the brushes and the commutators. This arcing not only leads to the degradation of components but also poses a potential danger due to the creation of sparks. Brushless motors eliminate this risk because they don’t depend on physical brushes to conduct electricity. This improvement in reliability ensures a safer and more efficient operation.

Energy Efficiency: The Elimination of Energy Loss

By doing away with brushes and commutators, brushless motors operate with increased efficiency. This means less energy loss and consequently, less heat generated during operation. This results in cooler running motors, minimizing the risk of overheating and prolonging the life of the motor.

The Bottom Line: Durability and Reliability Guaranteed

When it comes to power tools, durability and reliability are critical factors to consider. Brushless motors offer enhanced longevity, improved reliability, and remarkable energy efficiency. With minimized wear, the absence of electrical arcing, and increased efficiency, screw guns powered by brushless motors are designed to outperform their brushed counterparts effortlessly.

Investing in a screw gun with a brushless motor not only ensures longevity and reliability but with their virtually maintenance-free operation, they also provide cost savings in the long run. So, why settle for less when you can achieve unparalleled performance? Upgrade to a screw gun with a brushless motor today!

Note: The comparison table or bullet points list can be added based on specific screw gun models or brands available in the market that emphasize the benefits of brushless motors.

The verdict on screw guns with brushless motors: uncovering the truth about their performance

In conclusion, screw guns with brushless motors unquestionably deliver significantly better performance. With increased power, speed, longevity of battery life, and overall durability, it is clear that choosing a screw gun with a brushless motor is an excellent investment for professionals and DIY enthusiasts alike. Based on the points covered in this blog post, it is highly recommended to opt for screw guns equipped with brushless motors for superior performance and efficiency.